SÜDPACK Newsletter

Receive regular updates about SÜDPACK, our products and sustainability topics.

Companies in the pharmaceutical, medical goods and life science industries are currently evaluating the packaging concepts that are used for their products. The reason – they are taking a more sustainable position and many have committed to science-based goals. And replacing packaging concepts that are not particularly environmentally friendly with a recyclable alternative serves as a building block for improving their eco-balance.

“At the moment, the legal situation in the pharmaceutical industry does not require compliance with recycling rates. Those who switch to recyclable packaging concepts now, however, are making an investment in their image, which will give them a competitive edge in the market,” emphasized Michael Hermann, Head of Research & Development at SÜDPACK Medica.

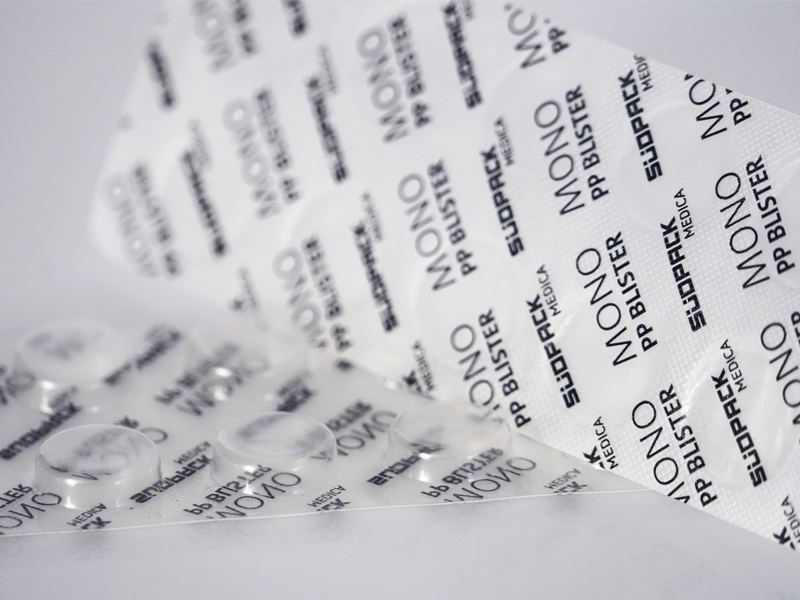

A blister concept with strong qualities

With its latest innovation, the PharmaGuard blister concept, SÜDPACK is setting standards in terms of both performance and sustainability. The PP-based top and bottom webs are manufactured in a unique coextrusion process and are perfectly coordinated, particularly when it comes to their sealing performance. This guarantees not only the highest packaging quality, but also maximum safety in a highly efficient process.

The bottom web offers a large processing window with excellent thermoforming performance and uniform demolding behavior. And despite the specific material features of PP films, SÜDPACK customers benefit in terms of processing as well. With only minor modifications to existing packaging lines, the materials can be processed safely and with optimal performance. This can be seen live in application for the first time at the beginning of May at interpack in Düsseldorf, at the IMA MAI S.A. booth, Hall 17, A20, and at Partena S.P.A. in Hall 15, A02.

For optimum product protection and maximum stability, the innovative material structures can be equipped with different barriers to suit the product to be packaged. “As a base material, PP naturally offers an outstanding water vapor barrier. Our coextrusion process makes it possible to also equip the material with barriers against oxygen and UV rays,” added Michael Hermann.

Compared to the other PP-based blister film solutions currently on the market, the SÜDPACK solution also stands out due to its very high transparency, which provides a clear view of the product.

Maximum material efficiency and a more favorable eco-balance

Thanks to the excellent material efficiency and low density of PP,

PharmaGuard saves a considerable amount of resources while maintaining high yields. As a complete mono-material solution, it can be allocated to existing material streams.

A life cycle assessment conducted by Sphera has proven that the packaging concept is associated with a greatly reduced climate impact (in CO2-eq) as well as lower energy and water consumption compared to other popular blister solutions.

SÜDPACK customers who would like to switch to a more sustainable packaging concept are actively supported by the film specialists at SÜDPACK Medica. Summing up the philosophy of SÜDPACK Medica in one concise sentence, Michael Hermann said: “As a one-stop supplier, our goal is to always offer customers the best possible alternative, one that is tailored to their unique requirements and from a single source – and to implement an optimal solution with a fast time-to-market.”

SÜDPACK Medica AG

Cordula Schmidt / Corporate Communications

Blegistrasse 7

CH – 6341 Baar

Press contact

REDAKON

Vera Sebastian

Seestrasse 18

D-80802 Munich, Germany

Phone: +49 (0) 89 – 31 20 338-21

E-Mail: vera.sebastian@redakon.com