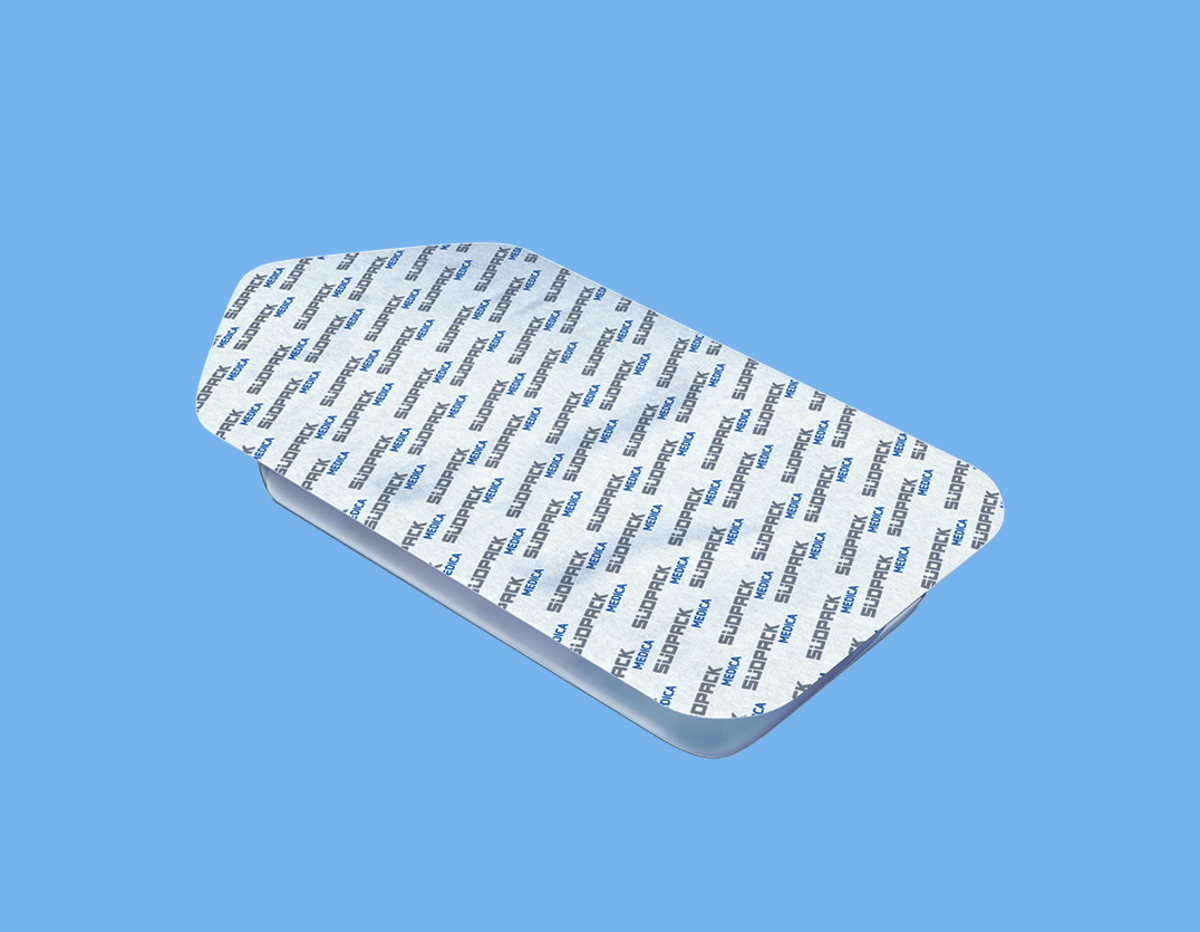

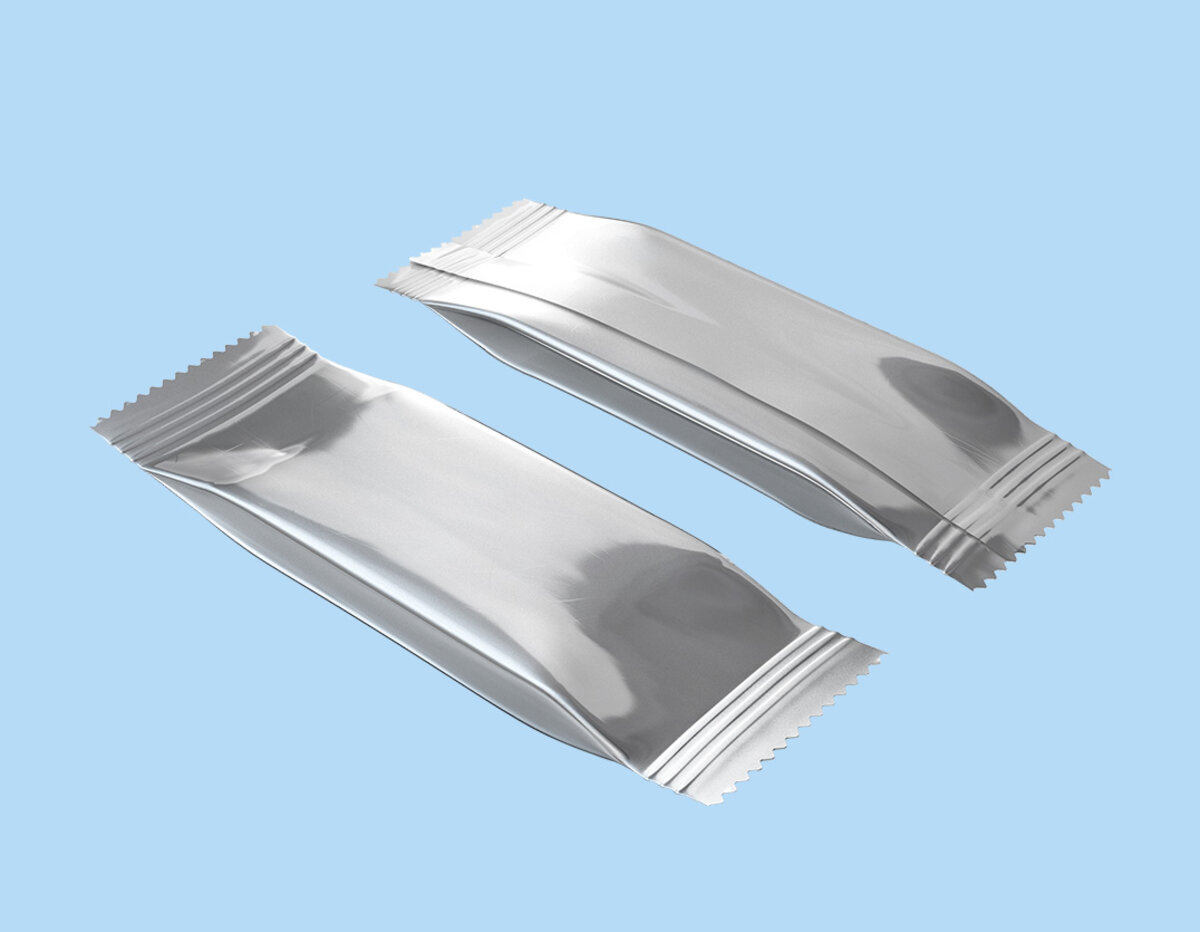

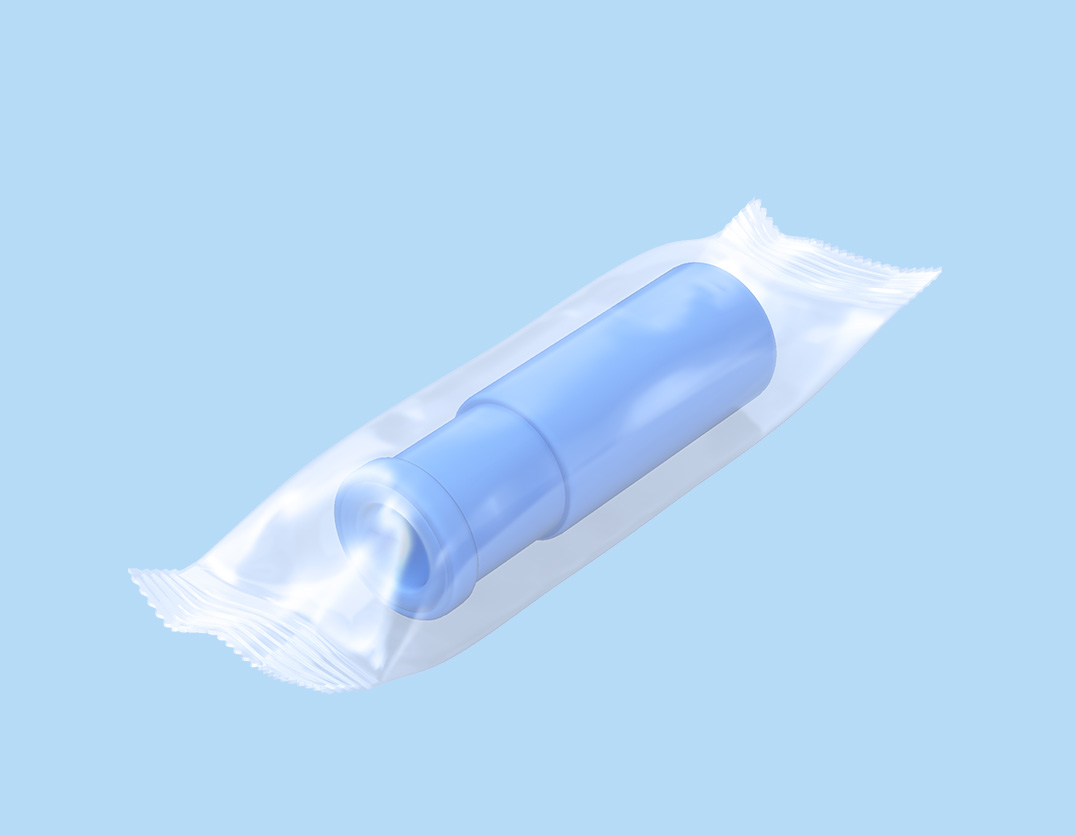

We enable circularity in Pharma and Medical

Sustainability is nothing new to us at SÜDPACK Medica – it has been an integral part of our corporate culture and conduct for many years.

The health care sector contributes significantly to the climate crisis. 71% of total health care greenhouse gas emissions fall under Scope 3 of the supply chain, i.e. they are caused by production, packaging, transportation and disposal. With our sustainable and recyclable packaging solutions, we aim to reduce these emissions within the industry.

More about sustainability at SÜDPACK