SafePeel Clear NT can be used on standard thermoforming packaging machines and tray sealers. Its wide processing window ensures optimal output.

SÜDPACK Newsletter

Receive regular updates about SÜDPACK, our products and sustainability topics.

The new SafePeel® Clear NT is a next-generation laminated film that combines high transparency with exceptional material efficiency. At just 37 μm, it is more than 25% thinner than its predecessor (52 μm). It also boasts a significantly reduced carbon footprint – up to 33% lower than the previous SafePeel Clear, based on internal calculations.

One of its standout features is its excellent sealing performance. Even in the presence of contamination, this laminated lidding film seals reliably to mono-PP trays. It is also designed to separate from the mono tray during the recycling process using the float-sink method, enabling efficient sorting into the appropriate recycling streams.

For extended product shelf life, SafePeel Clear NT can be equipped with a high barrier and optional antifog function. Its integrated peel feature makes opening easy and intuitive for consumers.

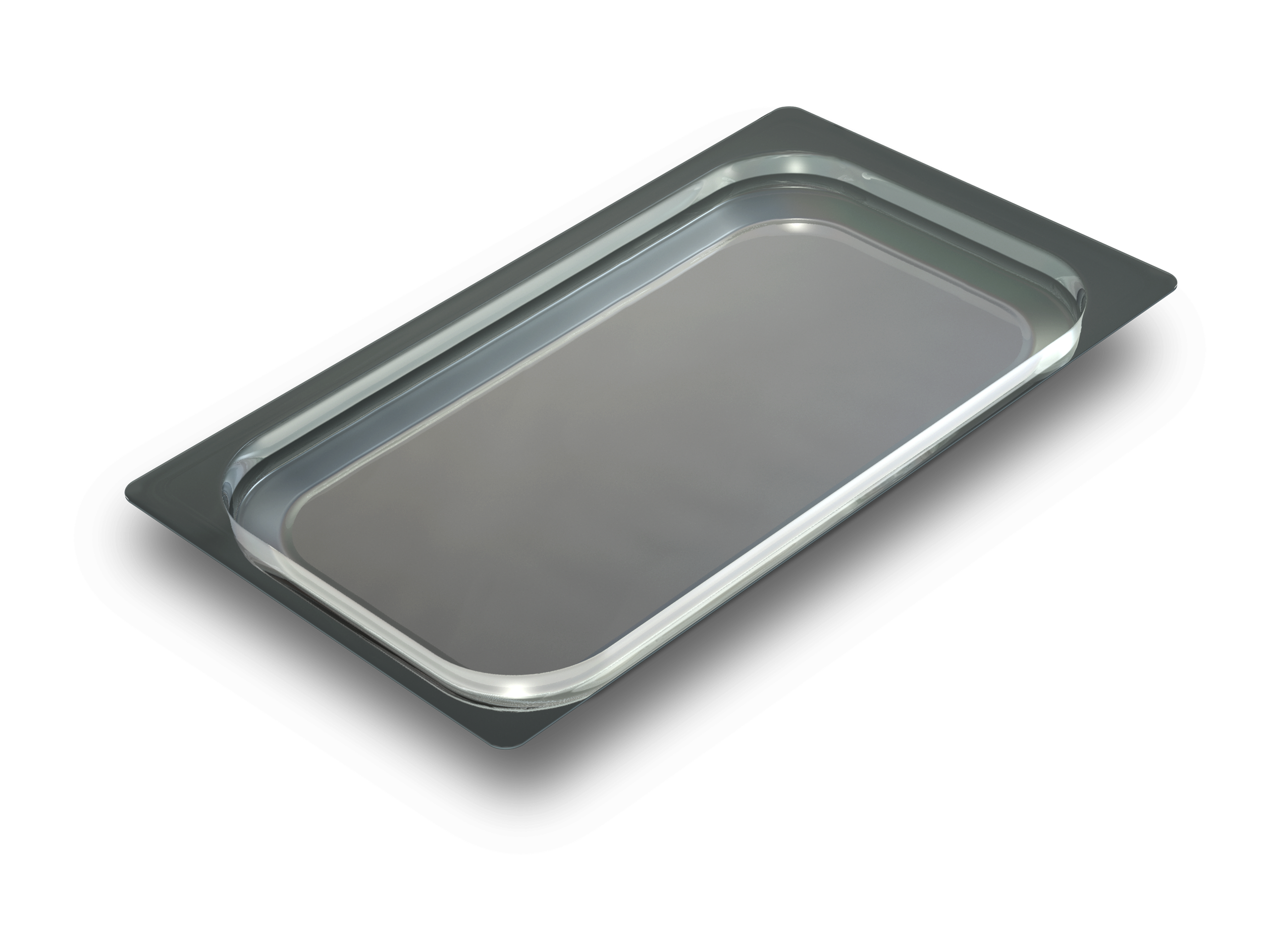

Lidding Films in Focus: The Key to Sustainable, Recyclable Packaging

SafePeel Clear NT can be used on standard thermoforming packaging machines and tray sealers. Its wide processing window ensures optimal output.

The films feature SÜDPACK’s proven peel functionality and are equipped with a high oxygen barrier – providing excellent product protection.

These transparent films are easy to print and coat, making them ideal for distinctive product presentation at the point of sale.

Exceptional material efficiency – delivering maximum product protection with minimal additional weight. In addition, the films are designed for recycling via the float-sink process.

The films can be enhanced with antifog and antistatic properties.

Our bottom films offer the perfect combination with our top films.

This results in packaging concepts that are groundbreaking in terms of efficiency, packaging security and sustainability.